LSI’s Coffee Production System is designed from the ground up to act as a coordinated process.

CPS works with existing facilities as well as for greenfield roasting systems and is flexible, scalable, and configurable to fit your facility’s needs.

Capabilities

CPS is designed to be modular and scalable, with the following components:

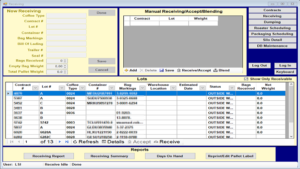

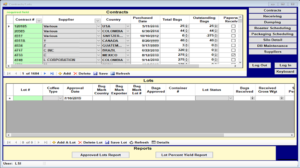

Click the image to enlarge. Order/contract tracking with futures

- Coffee receiving and dumping with or without barcode tracking

- On-demand reporting to determine dump schedule by production schedule and coffee type.

- Silo details/contents

- Blending recipe management

- Blend scheduling automatically sends charge to correct roaster

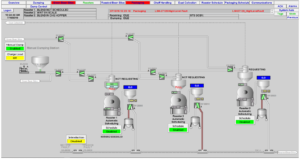

Click the image to enlarge. Roaster profiling

- Product genealogy and lot history

- OEE (Overall Equipment Efficiency)

- Predictive maintenance

- Computer-based training for operators, supervisors and maintenance

- Process data buffering, auto-reconnect to database and re-sync with stored data in PLC memory

- Ability to modify and run blending schedules with full data tracking even while being disconnected from the database (limited to available controller memory)

- Full report package: create and run custom reports from the SQL database.

Functionality

LSI’s CPS incorporates the production, recipe, and lot tracking data that is needed to successfully run any coffee plant.

CPS is highly integrated with the control system for maximum flexibility and robustness. CPS can also be remotely accessed and deployed at multiple sites and yet can remain integrated into the same database.

For example, a corporate buyer in New York City could enter the contracts for the purchased coffee from his or her office, while the coffee is received, blended, roasted, ground, and packaged in Seattle, Washington. The Chief Operations Officer can track the cost of production while on a business trip in Miami, Florida.

CPS has tremendous flexibility in creating and maintaining recipes.

There is no limit to the number of recipe items for a blend; the only limit is what is practical for your system. You can use the blend scheduling application to set the production schedule for the duration needed and/or use the scheduling application to determine if the proper types of coffee in the proper amounts are in silo’s, in green inventory on site or have been purchased. Multiple roasters of different sizes and types can be accommodated. This feature allows for tight quality control and ensures consistency of taste from blend to blend.

Being able to run a coffee facility with full visibility into the entire product life cycle was just a dream even a few years ago. CPS makes this visibility not only achievable but practical and affordable as well.

Once the user experiences the power of knowing everything about the finished coffee product (whether in a bag, tub, or can), from its buying point to its packaging point, and everything in between, the user will wonder how they ever ran without it.

After listening to the requirements of your unique application, our coffee experts will successfully integrate CPS into your process to ensure that your operation runs smoothly and efficiently.

Our singular goal is to exceed the expectations of our customers. We base our reputation on it.