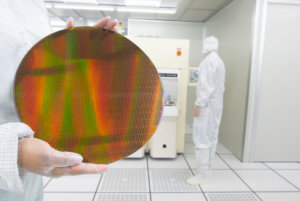

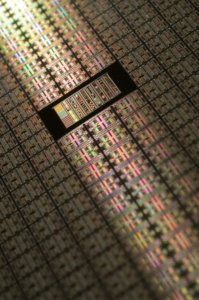

LSI provides services to support semiconductor material manufacturing (e.g., polysilicon) and advanced wafer processing facilities, to support the industry’s continued efforts to achieve increasing transistor densities as predicted by Moore’s Law.

The global semiconductor industry has grown significantly in the past few decades; 2020 average monthly sales exceeded the total sales revenue of 1987. As size, power consumption, and cost per transistor, have all come down (while speed has been increased), semiconductor components such as processors, memory, LEDs, etc., have made their way into more and more products. Due to such factors as improved device/system functionality, power consumption, and cost, we now see semiconductor components touching every industry.

This digital revolution was enabled by the continued advancement of semiconductor manufacturing and processing, which allowed semiconductor process nodes to shrink from 10 μm in the 1970s to 5 nm by 2020. To achieve this, the semiconductor industry has had to continually innovate, invest in production-related technologies, equipment, and manufacturing facilities, all while managing ever-tightening government environmental regulations.

LSI has decades of experience with many of the sub-systems utilized in today’s modern semiconductor foundries, and has experience supporting client’s needs to meet government regulations such as the U.S.’s Environmental Protection Agency (EPA) regulations (e.g., emissions management and reporting, waste, etc.).

Cleanroom Facilities

Controlled environments are critical for manufactured products, especially semiconductors. LSI provides a broad range of services to support systems found in today’s semiconductor manufacturing facilities, including:

- Industrial HVAC

- Air handling solutions

- Air-supply & distribution, re-circulation, pressurization

- Filtration (mechanical & electrostatic)

- Environmental control (temperature, humidity, pressure)

- Gas and water systems

- De-ionized, reverse osmosis

- Compressed air/gas, vacuum systems

- Piping

- Safety systems: building fire alarm & hazardous gas

- Monitoring systems and recording of control data

- Energy conservation, and more

Environmental Regulations

Complying with government regulations requires a commitment to excellence, robust systems, and processes. LSI’s knowledge and experience will deliver the monitoring, control for processing, and reporting systems needed to ensure all requirements are met.

Continuous Emissions Monitoring (CEM) & Reporting

- Compliance with the US government’s EPA is critical in avoiding environmental pollution and government fines

- National Emission Standards for Hazardous Air Pollutants (NESHAP) for semiconductor manufactures

- LSI is experienced in supporting client’s emission monitoring requirements (VOC, etc.)

- Solutions to support EPA compliance and EPA reporting

- Example services

- Installation of emission monitoring sensors

- Collection of emission data

- Real-time monitoring, visualization dashboards, & alerting of potential events

- Development of emissions report

- Waste gas treatment

- Burner/scrubber systems

Read our success story here.

Semiconductor Wastewater Treatment

- EPA Electrical and Electronic Components Effluent Guidelines for semiconductor manufacturing

- Discharge quality regulations require solutions for fab generated waste:

- CMP (Chemical Mechanical Planarization/Polishing),

- BG (Backgrinding),

- Acidic/Alkaline,

- Organic, etc.

- Example Service

- Neutralization & treatment for wastewater

- Multi-treatment units, skids, piping racks, PLC controls

- Flow, temperature, pressure, and resistivity monitoring

- PH neutralization

- Removal of fluoride, NH3, copper, etc.

- Monitoring and reporting

- Neutralization & treatment for wastewater

Visit our Water and Wastewater page for more information.

Automation & Controls

LSI is proficient with recognized industrial platforms including Rockwell Automation, Siemens, Emerson, and Wonderware, among others. Our engineers have implemented projects ranging in size from just a few points to over 20,000 point systems.

LSI is well suited for any applications involving the following:

- Power and Drive Systems – Siemens, Rockwell, GE, ABB

- DCS – Emerson DeltaV, Plant PAX, Honeywell, ABB, Provox, Foxboro

- PLC – Allen Bradley, Modicon, Siemens, GE, Omron

- HMI – Invensys & Wonderware, Iconics, Cimplicity, FactoryTalk, Intellution

- Plant Historian – OSI PI, Industrial SQL & Rockwell

- I/O Bus – HART, ASIbus, Profibus, ControlNet, DeviceNet & Foundation Fieldbus

- UL panel fabrication

Visit our Automation and Controls page for more information.

Electrical & Instrumentation

From overall plant power designs, coordinated drive systems and short circuit studies to instrument specification and valve sizing LSI has the depth of experience needed to ensure project success. Our employees have many years of experience with power distribution in plants, and we help clients understand and meet the challenges of NFPA-70E, Arc Flash studies. All of our electrical staff are fully safety trained and maintain a NFPA 70E certificate.

Our Electrical and Instrumentation capabilities include:

- Electrical Drawings, Specifications and Manuals

- Safety Systems

- Control System Upgrades

- Control System Troubleshooting and Optimization

- Power Distribution

- NFPA 70E Arc Flash

- Short circuit analysis

- Process Instrumentation Specifications

- Emergency Power and Lighting Systems

- Substations

- UL Control Panel Design and Fabrication

- Grounding Systems

- DCS and PLC Communications

- Fiber Optics

- MCC design

- CADD design

Visit our Electrical & Instrumentation page for more information.

How we work: LSI LISTENS

To deliver superior operational solutions that are simple, robust, and easy to maintain, it takes more than excellent engineers and programmers. We start by listening, learning, and understanding our clients’ processes and business drivers. Our relentless pursuit of understanding our client’s needs has helped LSI gain a highly-respected position in the semiconductor industry. LSI has also filled the gaps that our clients were asking us to fill. We’ve built up numerous complimentary in-house capabilities to add more value to our service offering, including project and construction management, procurement, process & mechanical engineering, machining & fabrication capabilities, as well as three panel shops worldwide.

To deliver superior operational solutions that are simple, robust, and easy to maintain, it takes more than excellent engineers and programmers. We start by listening, learning, and understanding our clients’ processes and business drivers. Our relentless pursuit of understanding our client’s needs has helped LSI gain a highly-respected position in the semiconductor industry. LSI has also filled the gaps that our clients were asking us to fill. We’ve built up numerous complimentary in-house capabilities to add more value to our service offering, including project and construction management, procurement, process & mechanical engineering, machining & fabrication capabilities, as well as three panel shops worldwide.

Our singular goal is to exceed the expectations of our customers. We base our reputation on it.