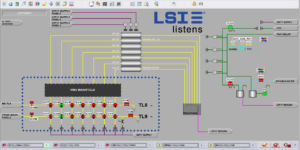

Mix-Proof Valve Manifold Design And Fabrication

Product contamination, limited space, safety hazards, frequent changeovers, and cleaning challenges are common concerns when a process-driven operation uses hoses and swing panels to route product flows. LSI can help mitigate these concerns, and it starts with listening. Each application is unique, and understanding our client’s process and objectives is our top priority. By combining our understanding of the client’s process and our decades of food and beverage experience, we can design a mix-proof valve manifold that improves safety, automates and optimizes the process, and minimizes installation space.

Our Seamless In-House Process

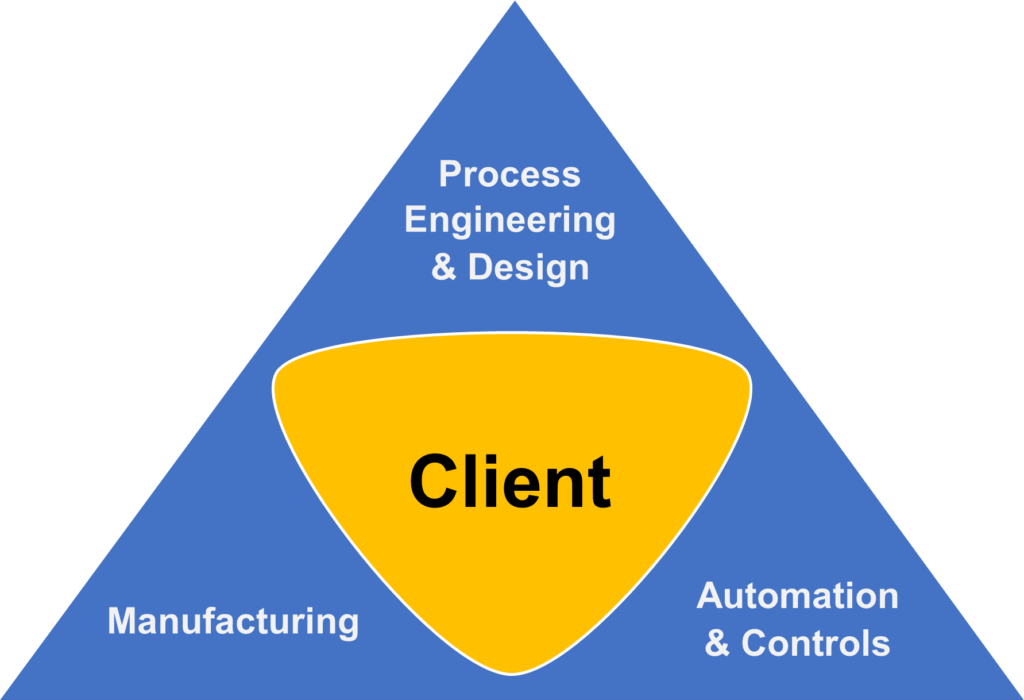

Our client is the center of LSI’s seamless in-house process and includes conceptual process design, manufacturing and fabrication, testing, technical construction oversite, piping coordination, installation, and commissioning.

Purpose of mix-proof valve manifolds

Mix-proof valve manifolds function as the traffic cop in the process of product/ingredient flow and clean-in-place (CIP) systems. Some valves can be open, while others are closed to restrict flow. It may sound simple, but it takes more than a working knowledge of pumps, valves, and controls to design and deliver a solution that meets the specific process and design requirements.

Mix-proof valve manifolds function as the traffic cop in the process of product/ingredient flow and clean-in-place (CIP) systems. Some valves can be open, while others are closed to restrict flow. It may sound simple, but it takes more than a working knowledge of pumps, valves, and controls to design and deliver a solution that meets the specific process and design requirements.

LSI's Process Design Team

LSI’s experience goes back to the introduction of the first mix-proof valves in North America. Many of our engineers have previously worked for valve manufacturers, breweries, dairy production, and specialty chemical plants. This diverse history brings decades of process engineering, automation, and controls depth to our client projects.

How We Work

As an outcome-driven company, LSI is constantly looking for ways to accelerate the delivery of client solutions. That mindset has fueled our growth as a global systems integrator. Our mix-proof valve manifold design is a case-in-point of our approach. Clients no longer have to contract with multiple vendors and face inherent communication and accountability challenges.

Project coordination is simplified and optimized by providing the client with all of the necessary capabilities and expertise. LSI becomes the single source of accountability for performance, schedule and budget, allowing the client to focus on their business.

While some systems integrators have various “divisions” that support the client, LSI believes there is a better way, and our clients agree. We approach it as a “fusion” of capabilities to provide a complete solution. This fusion results in the close interaction of disciplines including:

- Process engineering and design

- Process design

- Preliminary designs to develop budget requirements

- Detail designs for operation in the plant and provide detailed equipment lists.

- 3D Construction Drawings

- Process design

- Manufacturing

Automated precision orbital welding. Complete fabrication of manifolds, including orbital welding

- We do not manufacture valves, but we can provide purchasing, receiving, and administration related to securing the valves while leveraging LSI’s purchasing power or existing customer purchasing agreements.

- Pre-wiring

- Advanced fabrication of the manifolds using orbital welding and the latest techniques in fabrication

- Automation and controls

- Control system design (software and hardware)

- Installation and commissioning

Prior to sandblasting. Our automation and controls team is integrated from concept through fabrication to prepare the manifold for a push-button start-up, including pre-wiring, pre-testing, and setup. This results in fewer hours spent at client location during startup and an overall reduction in the project schedule.

- By the time a manifold is delivered, the transition from process design to automation startup is already ingrained in the internal process. Automation has been part of the “team” since the preliminary design, and their input often has a positive impact on the final design

Technologies

Staying at the forefront of technology is essential for our customer’s success and LSI’s growth. LSI is continually learning and adapting to the changing technology landscape, and this ensures the design and delivery of superior, cutting-edge, operational solutions.

LSI works with hardware OEMs including but not limited to:

LSI Listens

After listening to your unique application requirements, our team will successfully design, manufacture and commission the right mix-proof valve manifold for your operation.

Our goal is to help our clients be successful by exceeding their expectations throughout the project. We base our reputation on it.